Are Auto Darkening Welding Helmets the Best Choice?

Auto darkening welding helmets are an excellent choice for welders seeking enhanced protection and convenience. These helmets utilize advanced technology to adjust the lens shade in response to the brightness of the welding arc, thereby ensuring optimal visibility and safety. However, potential buyers should familiarize themselves with the various features and limitations of these helmets to make an informed decision.

Understanding Auto Darkening Technology

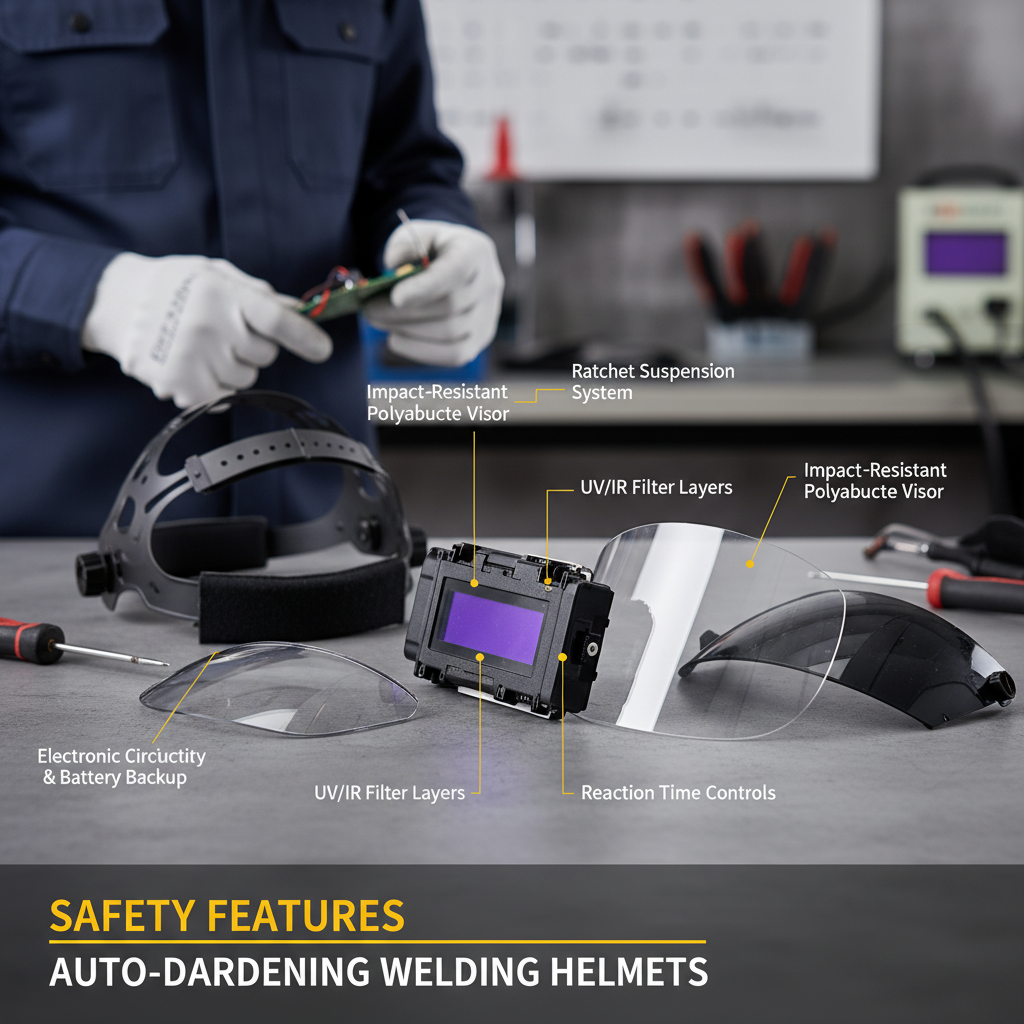

Auto darkening helmets employ sophisticated sensors to detect changes in light levels produced by the welding arc. When a welder strikes an arc, these sensors trigger a rapid adjustment of the lens shade, typically within milliseconds. This instantaneous reaction is crucial for protecting the welder’s eyes from harmful ultraviolet (UV) and infrared (IR) radiation and ensures that visibility remains clear during the welding process. The technology is not only about protection but also about enhancing the overall welding experience; a clear view of the weld pool allows for better precision and control, which leads to improved weld quality.

Advanced models often feature multiple shade settings, allowing for customization based on the specific welding task at hand—such as MIG, TIG, or stick welding—each of which may require a different level of lens darkness. This flexibility is particularly beneficial for professionals who switch between various welding processes frequently.

Safety Features to Consider

When selecting an auto darkening welding helmet, safety features should be a top priority. A minimum shade rating of 10 is generally recommended for adequate protection against UV and IR light. However, many experts suggest that for high-intensity welding, a shade rating of 11 or higher may be more appropriate.

Beyond the basic shade rating, additional features like adjustable sensitivity and delay settings can significantly enhance safety and comfort. Adjustable sensitivity allows the helmet to respond to different arc intensities, which is especially useful in environments where welding conditions may vary. Delay settings enable users to control how long the lens remains dark after the arc is extinguished, preventing accidental eye strain from lingering brightness. Furthermore, helmets with a built-in grinding mode offer added versatility, allowing the user to switch to a lighter shade for non-welding tasks without having to remove the helmet.

Pros and Cons of Auto Darkening Helmets

Auto darkening helmets come with a range of advantages that make them appealing to both professional and hobbyist welders.

– Pros:

– Improved Visibility: The ability to maintain a clear view before and after striking an arc allows for greater precision in welding.

– Comfort During Long Sessions: These helmets reduce the need to lift the helmet frequently, thereby minimizing fatigue and discomfort during extended welding sessions.

– Less Eye Strain: Quick transitions between light and dark shades help decrease eye strain, which can be particularly beneficial for welders working on intricate projects.

– Cons:

– Higher Cost: Auto darkening helmets are typically more expensive than their passive counterparts, which can deter budget-conscious buyers.

– Battery Life: Many models rely on batteries, which can fail unexpectedly, leading to potential downtime during critical projects. It’s essential to periodically check battery levels and consider models with solar assist to prolong usage.

– Sensor Malfunctions: In rare cases, the sensors may fail to respond correctly, compromising safety. Regular maintenance and testing are essential to ensure reliability.

Common Misconceptions

There are several misconceptions surrounding auto darkening helmets that can lead to confusion among potential users. A prevalent belief is that these helmets are exclusively for professionals. In reality, auto darkening helmets can significantly benefit hobbyists as well, providing them with enhanced visibility and comfort, which is crucial for achieving high-quality results in their projects.

Another misconception is the idea that auto darkening helmets can replace safety glasses. While these helmets provide substantial protection, they are designed to be worn in conjunction with other forms of eye protection, such as safety glasses or goggles, to ensure comprehensive safety against flying debris and other hazards present in the welding environment.

Choosing the Right Helmet

Selecting the right auto darkening welding helmet involves careful consideration of various factors. First, assess your welding environment—whether you are working indoors or outdoors, and the types of welding you will be performing—MIG, TIG, or stick welding. Each of these processes may require different helmet specifications.

Next, think about your personal comfort. Helmets come in various designs, weights, and fitting options, so it’s essential to try on different models to find one that feels comfortable during long sessions. Additionally, researching brands and reading reviews can provide insight into which helmets have the best safety features and user satisfaction.

Look for helmets that meet relevant safety standards, such as ANSI Z87.1 or ISO 4871, which ensure that the helmet has undergone appropriate testing for durability and protection.

Maintenance Tips for Longevity

Proper maintenance is crucial for ensuring the longevity and effectiveness of your auto darkening welding helmet. Regularly cleaning the lens is essential to maintain optimal visibility and performance. Use a soft, lint-free cloth and a gentle cleaning solution to avoid scratching the lens surface.

When not in use, store your helmet in a protective case to prevent damage from impacts or environmental factors. It is also advisable to conduct routine checks on the helmet’s battery and sensors to ensure they are functioning correctly. Keeping the helmet in a cool, dry place will help extend its lifespan and reliability.

Expert Recommendations

To ensure that you select the best auto darkening welding helmet, consider consulting reviews from professional welders and industry experts. These insights can provide valuable information about which models offer the best safety features and performance. Check for certifications like ANSI or ISO, as these indicate that the helmet meets established safety regulations.

Participating in welding forums or attending local welding workshops can also be beneficial. Engaging with experienced welders can provide firsthand insights into the pros and cons of different helmet models, helping you make a well-informed choice.

In conclusion, auto darkening welding helmets can be a safe and efficient choice for welders when the features and specifications are fully understood. By prioritizing safety, comfort, and quality, and by selecting a helmet that meets industry standards, you can significantly enhance your welding experience. Be sure to explore your options carefully and invest in a helmet that will serve you well for years to come.

References

- https://en.wikipedia.org/wiki/Welding_helmet

- https://www.cdc.gov/niosh/docs/2004-100/default.html

- https://www.osh.gov.au/oshanswers/hsprograms/welding.html

- https://www.welding.org/welding-helmets

- https://www.thefabricator.com/article/welding/understanding-welding-helmet-options

- https://www.cdc.gov/niosh/nioshtic-2/20028442.html

- https://www.safetyandhealthmagazine.com/articles/17025-how-to-choose-the-best-welding-helmet

- https://www.ansys.com/en/resources/tech-briefs/what-to-know-about-welding-helmets