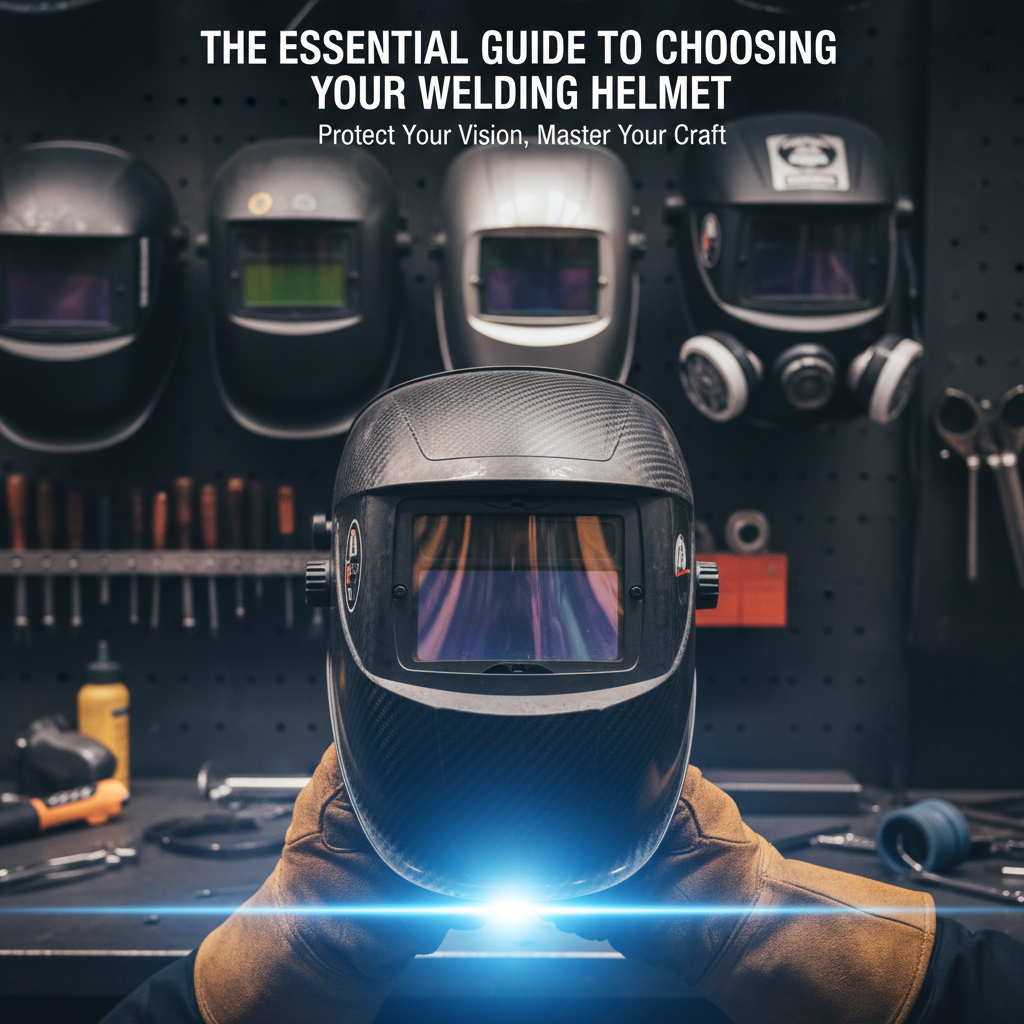

The Essential Guide to Choosing Your Welding Helmet

To choose the right welding helmet, prioritize safety features, lens type, and comfort. A proper helmet not only protects your eyes but also enhances your welding experience and efficiency. Selecting the right helmet is vital for every welder, whether you are a beginner or a seasoned professional. The market is filled with options, each designed to cater to different welding techniques and personal preferences. Understanding these factors can help you make an informed decision that ensures your safety and productivity on the job.

Understanding Welding Helmet Types

When it comes to welding helmets, the first distinction to grasp is between auto-darkening and fixed shade helmets. Auto-darkening helmets feature lenses that automatically adjust their tint in response to the brightness of the welding arc. This allows for greater convenience, as welders do not need to manually flip the helmet down or change the lens. It’s particularly beneficial for processes requiring frequent switching between welding and non-welding tasks, as it enhances visibility and reduces eye strain.

On the other hand, fixed shade helmets come with a single, predetermined lens shade. While they tend to be more affordable, they require the user to lift the helmet for visibility when not welding, which can be cumbersome. Fixed shade helmets might be suitable for hobbyists or those who engage in welding infrequently, as they offer adequate protection without the added features of higher-end models.

Specialty helmets are another option to consider, as they cater to specific welding techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas). For instance, TIG welding often requires a lighter shade and higher sensitivity to ensure precision, while MIG welding can benefit from a helmet that allows for quick visual adjustments. Understanding the nuances of each welding technique can guide you toward a helmet that best fits your particular needs.

Key Safety Features to Look For

Safety is paramount when selecting a welding helmet, and certain features can significantly enhance your protection. One of the primary aspects to consider is impact resistance. A helmet should meet or exceed safety standards set by organizations such as the American National Standards Institute (ANSI) or the Canadian Standards Association (CSA). Helmets that are designed to withstand impact from flying debris, sparks, and heat will provide an essential layer of protection while you work.

Another critical safety feature is UV/IR protection. Ultraviolet (UV) and infrared (IR) rays can cause severe eye damage, including burns and long-term vision problems. Look for helmets that offer sufficient UV/IR protection ratings, ideally up to shade 16, to ensure that your eyes are shielded from harmful rays during the welding process. Investing in a helmet that provides comprehensive protection can prevent serious injuries and contribute to your overall well-being.

Lens Technology Explained

Lens technology plays a fundamental role in the overall functionality of a welding helmet. Traditional lenses are basic and offer a fixed shade that is not adjustable, which can limit visibility and adaptability in different welding environments. While they are often less expensive, traditional lenses may require you to pause your work to change the lens shade, which can be inefficient.

In contrast, auto-darkening lenses offer a significant advantage in terms of visibility and convenience. These lenses automatically adjust to varying light conditions, allowing welders to maintain clear vision both before and during the welding process. This technology not only improves comfort but also enhances the quality of work by providing accurate visibility of the weld pool and surrounding area.

When selecting a welding helmet, the lens shade range is also crucial. Different welding applications require different shades to provide optimal protection and visibility. For example, a shade of 10-12 is generally recommended for MIG welding, while TIG welding may require a shade of 8-10. Understanding the appropriate lens shade for your specific welding task can greatly improve your efficiency and comfort while working.

Comfort and Fit Considerations

Comfort and fit are essential factors that should not be overlooked when choosing a welding helmet. A helmet that is too heavy or unbalanced can lead to fatigue, especially during extended periods of use. Look for helmets that are designed with weight distribution in mind, ensuring that they sit comfortably on your head without causing strain.

Adjustable features are another critical aspect of achieving a proper fit. Helmets should come equipped with adjustable headgear and padding to accommodate different head sizes and shapes. A customizable fit not only enhances comfort but also ensures that the helmet stays in place during operation, providing consistent protection. Additionally, consider helmets with ventilation systems to improve airflow and minimize heat buildup, allowing for a more comfortable welding experience.

Budgeting for Your Welding Helmet

When budgeting for a welding helmet, it is essential to familiarize yourself with the various price ranges and the features you can expect at each level. Entry-level helmets may cost between $30 and $100 and typically offer basic protection and fixed shade lenses. Mid-range helmets, priced between $100 and $300, generally include auto-darkening features and improved safety ratings.

Premium helmets, which can range from $300 to $1,000 or more, often come equipped with advanced technology, such as high-quality auto-darkening lenses, enhanced safety features, and superior comfort. While the initial investment may be higher, it is essential to consider the long-term benefits. A high-quality helmet can provide better durability, improved safety, and enhanced welding performance, ultimately saving you money over time by reducing the need for replacements and repairs.

Top Brands and Recommendations

Selecting a reputable brand can significantly influence the quality and reliability of your welding helmet. Industry leaders known for their high-quality helmets include Lincoln Electric, Miller Electric, and 3M. These brands have built a solid reputation for producing helmets that prioritize safety, comfort, and innovative technology.

User reviews can also provide valuable insights into the performance and durability of different models. Look for feedback from fellow welders regarding their experiences with specific helmets. This firsthand knowledge can help you narrow down your options and choose a helmet that aligns with your needs.

Maintenance Tips for Longevity

To ensure the longevity of your welding helmet, regular maintenance is crucial. Cleaning your helmet after each use will prevent the buildup of dirt, debris, and smoke that can obscure visibility. Use a soft cloth and gentle cleaner specifically designed for helmet lenses, avoiding harsh chemicals that may damage the lens.

Additionally, conduct regular inspections of your helmet for signs of wear and tear. Check the straps, headgear, and lens for any damage or degradation. Addressing any issues promptly can prevent further damage and ensure that your helmet continues to provide the protection you need.

Investing time in choosing the right welding helmet can significantly enhance your safety and efficiency while welding. By prioritizing safety features, lens technology, comfort, and proper maintenance, you can select a helmet that not only protects your eyes but also improves your overall welding experience. Whether you opt for advanced technology or a budget-friendly option, ensuring you have the proper protection is crucial for every welder.

References

- https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9761

- https://www.nsf.org/knowledge-library/welding-safety

- https://www.welding.org/resources/welding-helmet-guide

- https://www.cdc.gov/niosh/docs/2010-134/pdfs/2010-134.pdf

- https://www.aaon.com/welding-helmet-selection-guide

- https://www.fabtechshow.com/education/welding-helmet-selection-guide

- https://www.lni.wa.gov/safety-health/safety-topics/welding-safety